Polyamide Thermal Breaks

High Performance

Polyamide Thermal Breaks

Polyamide thermal insulation barrier profiles minimize heat transfer by thermally separating the inner and outer surfaces of aluminum window and facade profiles.

Thermole %25 Cam Elyaf Takviyeli Polyamid 6.6 Isı Yalıtım Bariyeri

HIGH TEMPERATURE RESISTANCE

This allows the barriers to be attached to the profile after... electrostatic powder coating oven (200°C) You can enter safely.

Mechanical Strength

Polyamide profiles have a thermal expansion coefficient compatible with aluminum profiles. They move along with aluminum during temperature changes.

COMPLIANCE WITH STANDARDS

Our products EN 14024 It fully complies with standards and meets mechanical properties such as shear strength and transverse tensile strength.

Precise Geometry

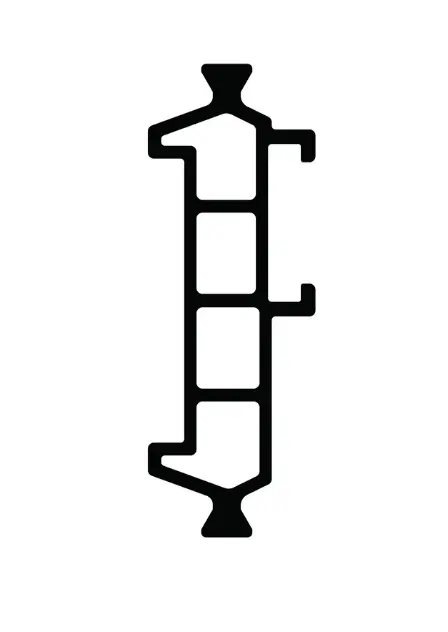

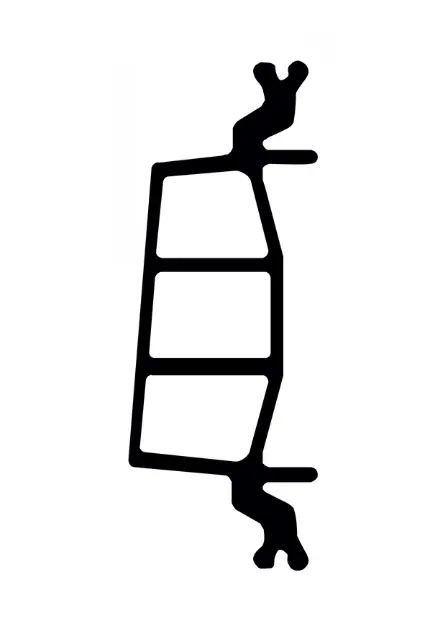

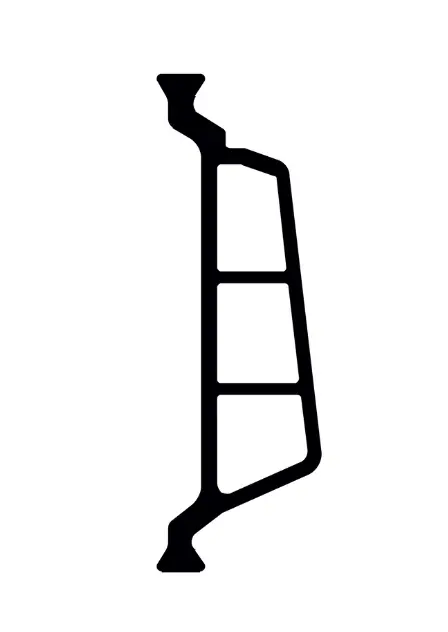

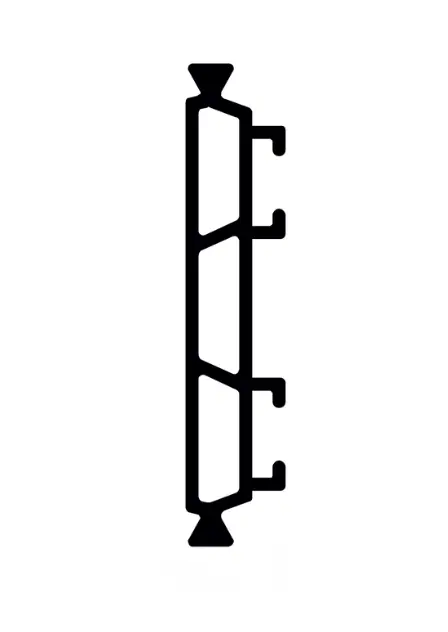

Our profiles are designed with precise tolerances to accommodate different insulation depths and suitable geometric shapes (I, C, T, Y, etc.) for various applications.

In addition to polyamide and PVC barriers; ASA, ABS Using other engineering plastics, we also produce custom connection profiles for your facade systems.

PROFILE DIVERSITY

Polyamide Thermal Breaks

- Low coefficient of thermal conductivity: 500 times lower than aluminium.

- Coefficient of thermal expansion: Similar to aluminium.

- Good resistance to high temperatures: Resistant up to 220°C, which allows installation on aluminium profiles before powder coating.

- Dayanıklılık: %25 cam elyaf içeriği sayesinde fiziksel darbelere, yaşlanmaya ve korozyona karşı dayanıklıdır.

- Resistance to UV radiation: Resistant to UV radiation due to the black carbon content and processing method.

- Chemical resistance: Resistant to most chemical products, cleaning and processing agents.

- Fire safety: Not exposed to salt acid gases and combustion residues are non-toxic.

- Savings on heating and cooling costs: No damp and cold surfaces, which contributes to energy savings.

- Environmentally friendly and recyclable: Complies with legal energy saving requirements and carbon emissions, environmentally friendly and recyclable.

THERMOLE is also the solution partner of its customers in injection products and moulds with its plastic injection unit.