Factory

Integrated Technology and Production Center

Our Ereğli Facility

In the Karadeniz Ereğli Organized Industrial Zone, 15,000 m² Our modern facility, built on an enclosed area, is a reflection of our more than 27 years of experience in plastics engineering.. In our factory, equipped with fully automated extrusion lines compliant with Industry 4.0 standards, all processes from raw materials to packaging are monitored in real-time via digital ERP systems.. Bu dijital altyapı, operasyonel mükemmelliği ve ürün izlenebilirliğini %100 oranında garanti altına almamızı sağlar.

Mold Shop: Flexibility in Design

R&D and Quality Control Laboratory

High-Capacity Extrusion

Environmentally Friendly, Sustainable Production

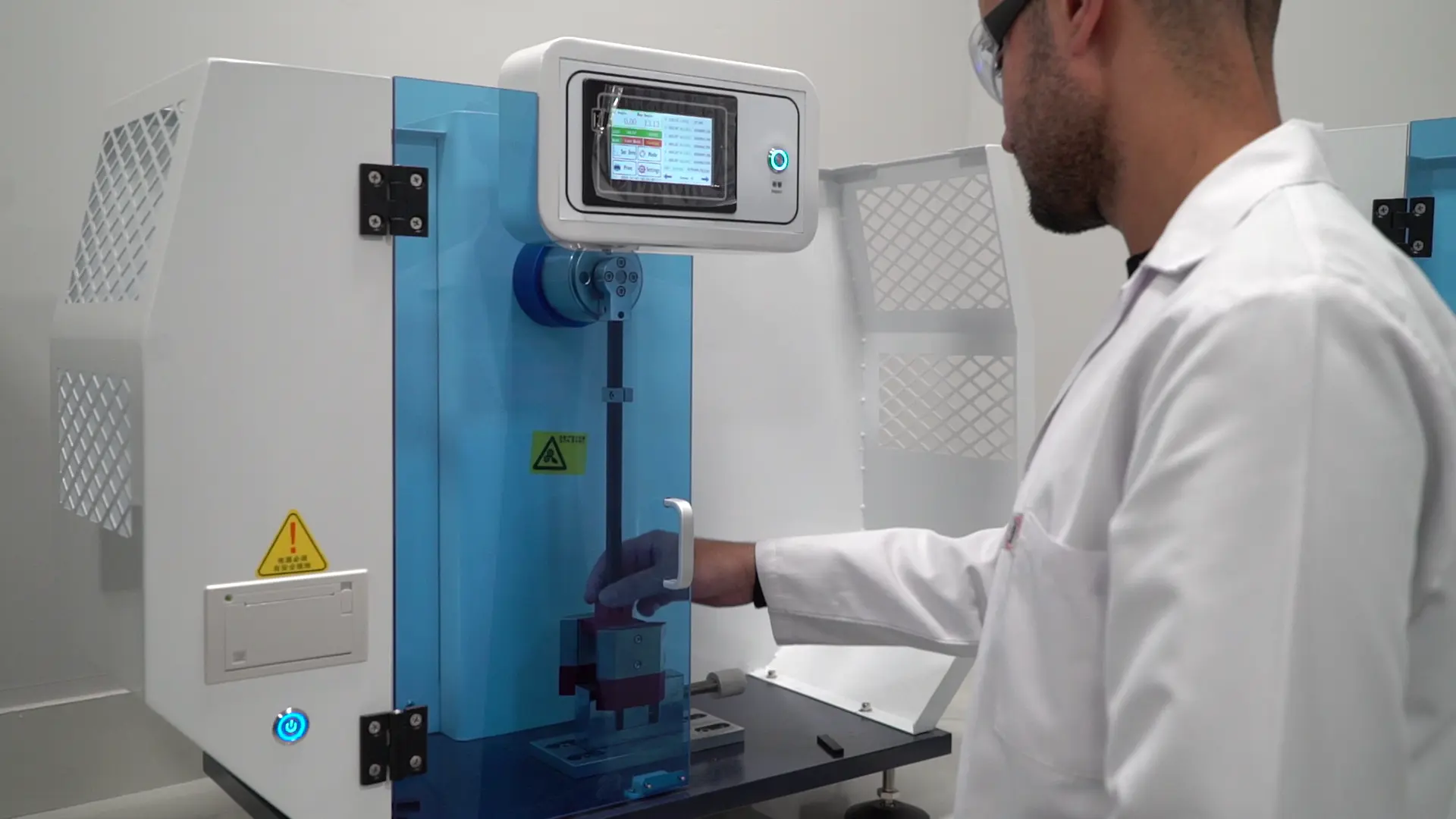

Lab

At THERMOLE, we conduct all quality tests to ensure excellence, from raw material selection to final product specifications. in our own laboratory We carry out the following. Our quality control processes include the following tests:

Test List:

Melt Flow Index (MFI), °C, EN ISO 11357-3

Glass Fiber Content Analysis, %, EN ISO 1172

Density Measurement, g/cm³, EN ISO 1183-1

Humidity Measurement, %

Shore Hardness Value, Shore D, EN ISO 868

Charpy Impact Resistance, kJ/m², EN ISO 179-1

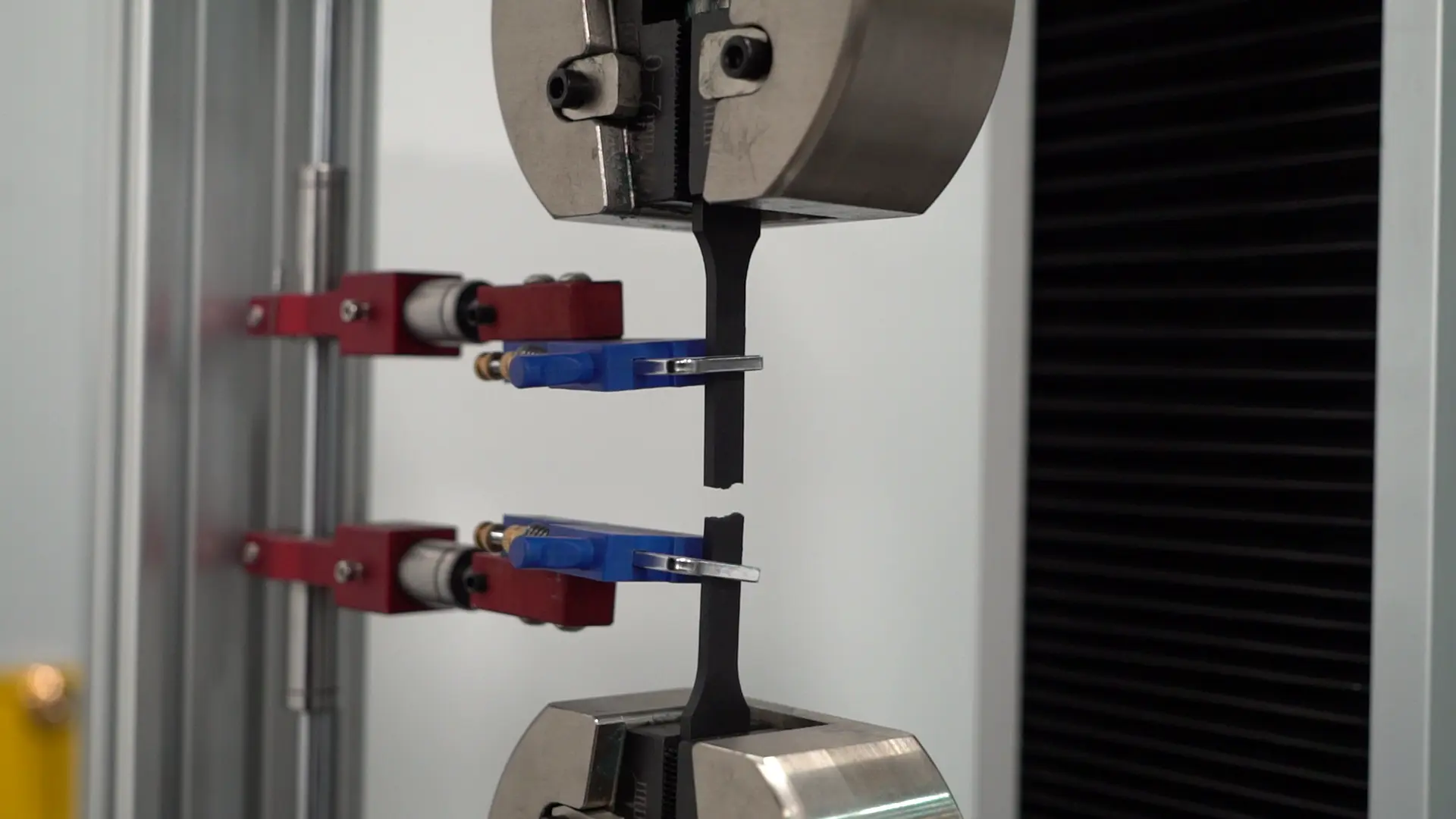

Tensile Strength, N/mm², EN ISO 527-1, EN ISO 527-2

Elongation at Break, %, EN ISO 527-1, EN ISO 527-2

All quality parameters are rigorously monitored, recorded, and archived before, during, and after production. This strict quality control system ensures the highest product standards and guarantees customer satisfaction.